Eliminate Production Waste

Empower your continuous improvement team with advanced Lean Six Sigma statistical tools. Our technology utilizes logic to analyze real-time data, detecting discrepancies and pinpointing root causes, even in the face of human error. With our advanced solution, your staff can achieve superior performance with minimal effort.

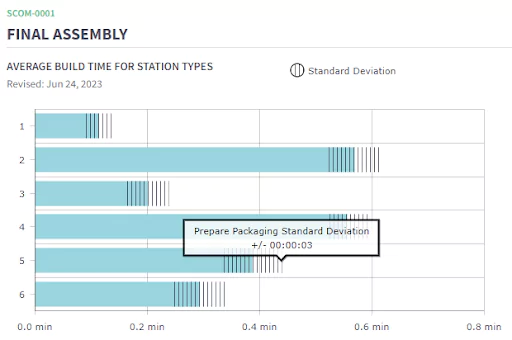

Step Standard Deviation

Our platform analyzes the individual tasks not only cycle times.

Even if Operators fail to record complications, the results will uncover challenges.

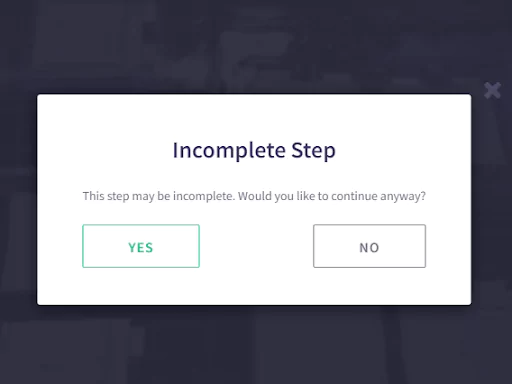

Skipped Task

Operators are warned if they are moving too fast or skip a step altogether.

Checkpoints can be used to verify Operator engagement.

Embed mandatory equipment signals to ensure all processes are completed.

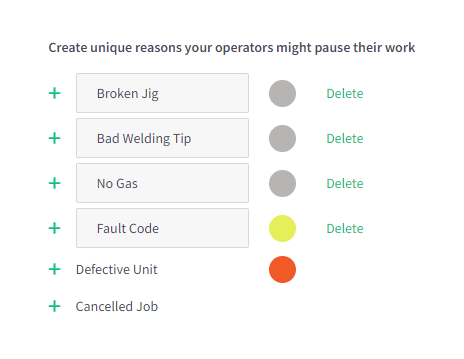

Customizable to Work Area

Create unique categories and pause reasons.

Assign different color codes to appear in ANDON.

Pareto Diagram

A powerful visual tool that helps identify the most important factors contributing to problems or outcomes by ordering them in descending importance. This chart tool allows you to prioritize your efforts and resources on the vital few factors that have the greatest impact, leading to significant improvements.

Root Cause Analysis

Easily pinpoint and measure production stops by zooming in to identify specific issues within your main categories. This streamlined process allows you to quickly locate and address the root causes of your greatest problems, leading to improved efficiency and productivity.

Find Hidden Waste

Visualize activity at your production cells or follow a specific Operator to better understand how to manage your workforce.

Operator Inactivity

Discover when Operators are idle at their station, or abandoning it altogether.

Read aboutYour Strategic Partner

Change is always great on paper, but tough to make real in a factory stuck in the last century. Our team of experts do nothing but assist manufacturers transform their factory to the digital world. They listen to your challenges, limitations, and organizational goals to assist you in creating a data-driven roadmap.

Learn more