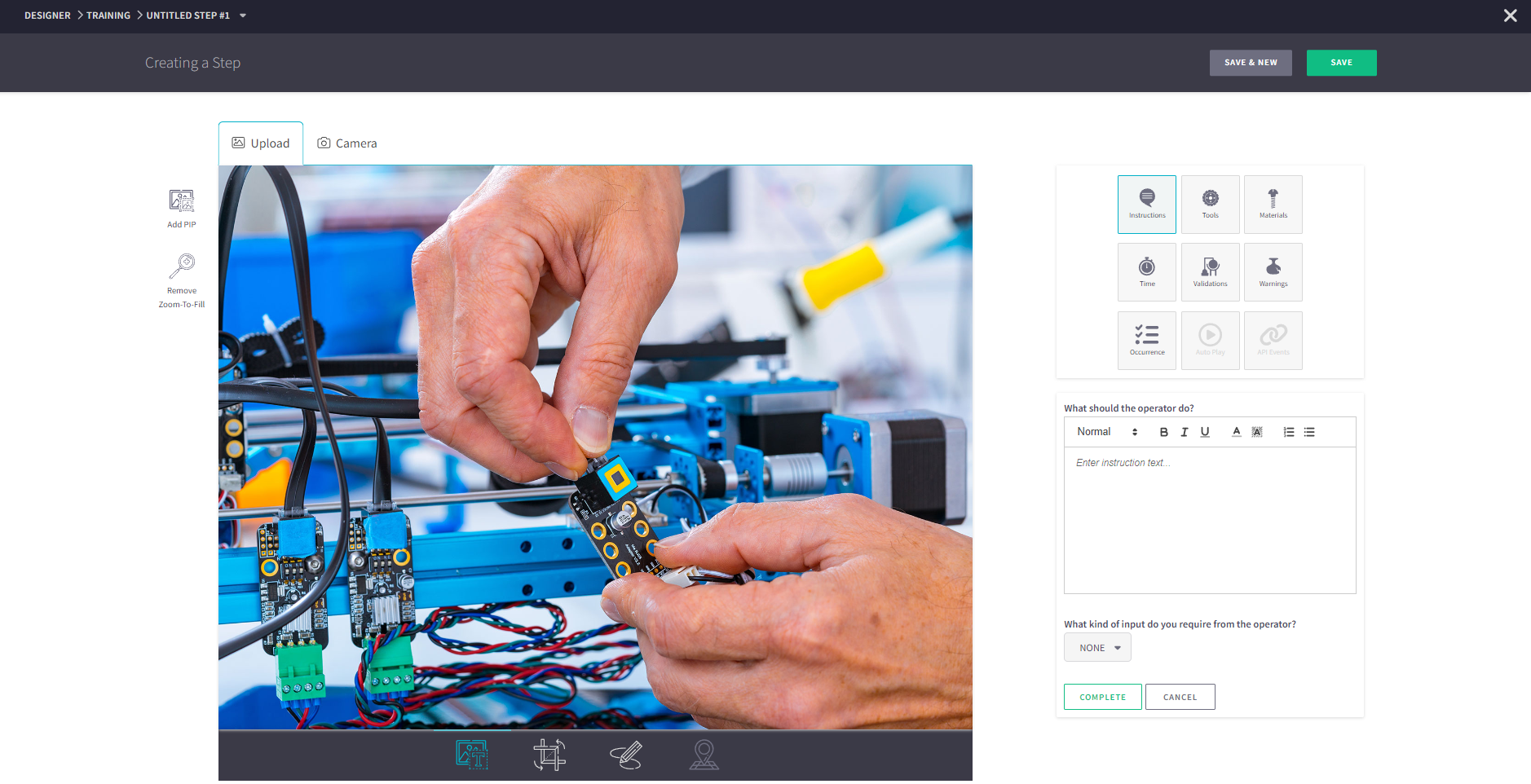

I have spent my career in Manufacturing, and witnessed first hand the difficulty in acquiring skilled labor, or training the skillset into new hires. Every factory I’ve ever visited has those unique individuals that possess unrivaled abilities that are virtually impossible to replicate. These operators can yield a higher throughput with higher quality, and unfortunately set the standard for expectations.

It is not a good business practice to rely so much on the ability of a person. Every vacation or sick day they take then directly impacts the throughput of a factory. These are the people that you must invest a small amount of time to record their skill through Work Instructions.

So Why make our Work Instruction Software Free?

Knowing the importance of Standard Processes, I am constantly educating the Manufacturing sector to create Work Instructions. When they begin to do so, many are reluctant to invest in any type of software and instead rely on Word/Excel or PowerPoint. Though at first this might seem like a great solution, those platforms are not made to create Work Instructions and can be far more time consuming, and lack revision control support. Worse yet, if the Manufacturer ever wants to transition to a Digital Factory they have to start all over as their documentation is not structured in a way to be useful.

Our platform can support them in creating higher quality Work Instructions, assisting them to successfully adapt their operations. The end goal is that they find success, and recognize some day in the future the profound benefits of digitalization. If and when this day comes, we hope that they select our company to be their strategic partner.

What’s the point in paying for our platform?

Our free Work Instruction Software is only one component of a major offering. What you can get for free is a fantastic start in standardization, but it does not come with Compass - which is necessary to transition to a digital factory. Compass automates data collection and analysis, and opens up opportunities to embed in-line quality assurance and machine monitoring.

It is highly likely that users of our free Work Instruction Software will one day realize that they are ready to achieve greater efficiency and quality, and the only way to do that is to integrate greater process control. When this day comes, it simply requires a “flip of the switch” and all their efforts in documentation will instantly become state-of-the-art with virtually no additional work.

When should you consider creating Work Instructions?

If you have a product that is repeatedly built, and your organization would benefit from greater efficiency - you should start today. Job shops that are able to over charge might not see as much of a need, as the essence of their operation benefits from the lack of efficiency.

This free Work Instruction Software is not a trial, there is no time limit, there is no catch. Whether you have minutes a week or hours to dedicate to documentation, this platform is meant to suit your needs.

So take a moment and sign up now, and share it with your colleagues to help move beyond the practice of relying on software that is not meant for Work Instruction documentation.

Ben Marsh

I've spent my career in Manufacturing, and can't stop trying to make things more efficient. At home, I am a master Lego builder with my son.

3 min read

3 min read