Crafting clear and effective work instructions is an art that balances precision with simplicity. In the bustling world of manufacturing and service industries, the ability to convey complex processes in an understandable manner is invaluable. Work instructions serve as the roadmap for quality, efficiency, and consistency, guiding teams through the intricacies of their tasks.

In this blog, we review 5 common processes and work instruction examples that are highly effective. Unlike engineering prints you may have used in the past, you’ll observe that these work instructions incorporate actual images from the production floor, capturing the essence of tribal knowledge. This approach not only enriches the learning experience but also significantly accelerates the onboarding process for new employees, immersing them in the real-world context of their tasks.

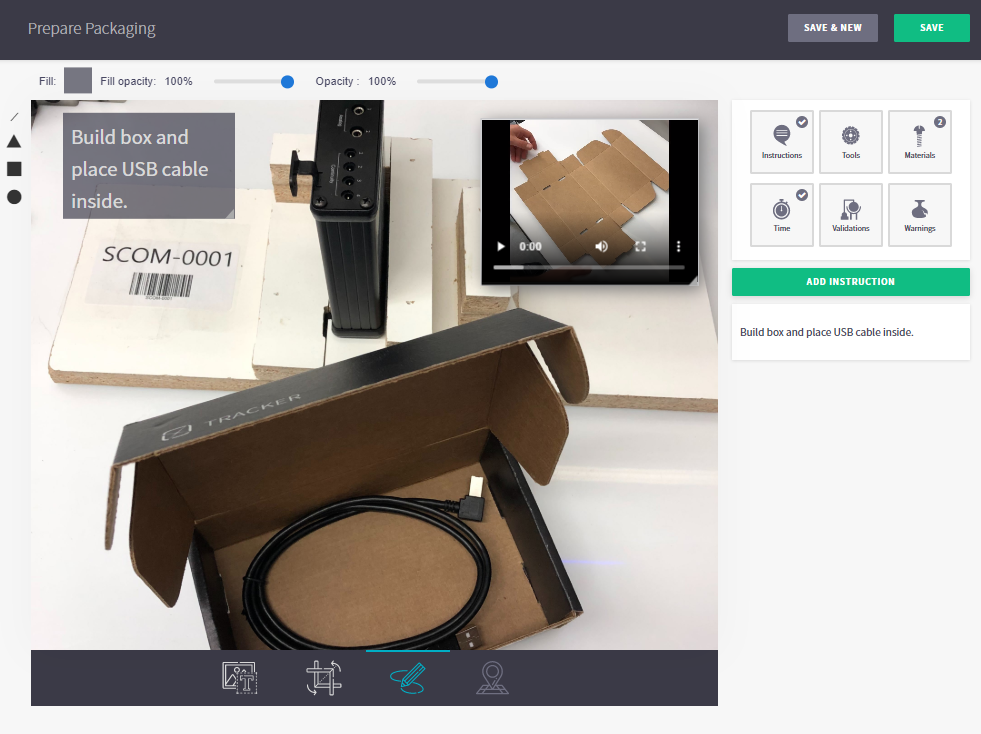

Work Instruction Examples 1: Assembly

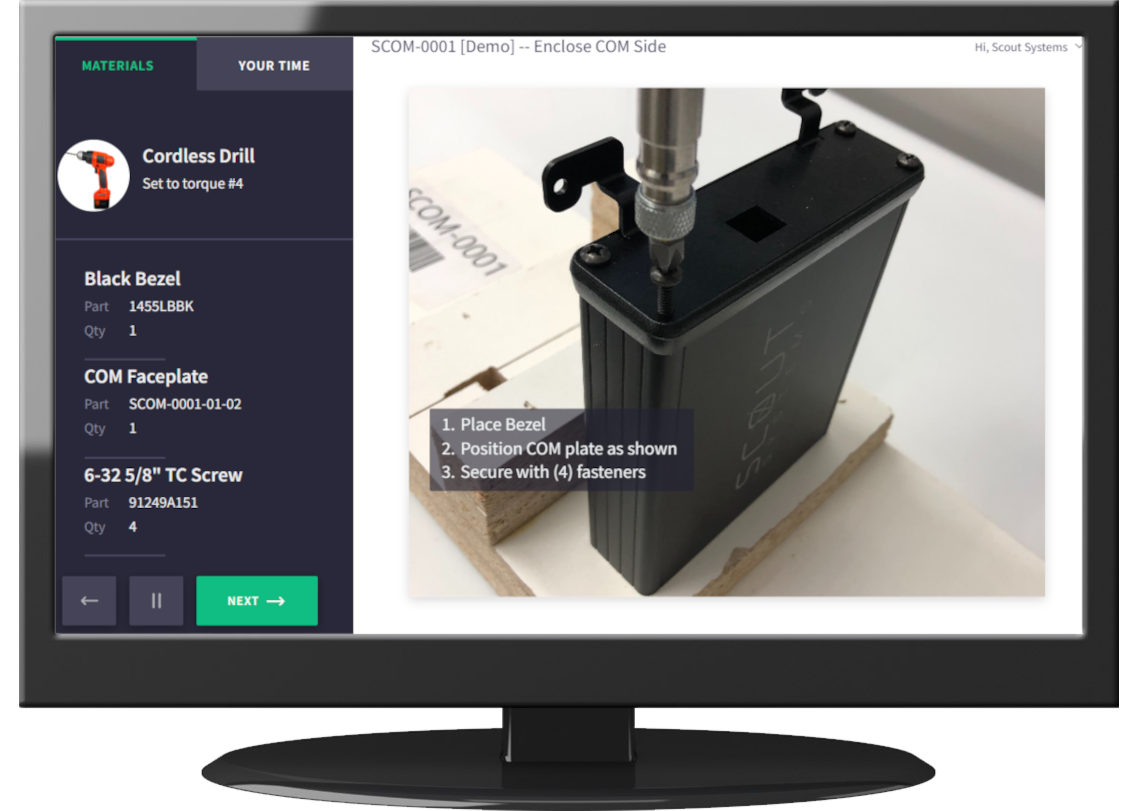

It’s our recommendation that work instructions should be concise and simple to digest, ensuring Operators receive only the essential information required for the task at hand. Instead of overwhelming them with a comprehensive bill of materials and tools list, work instructions should be streamlined to include only the materials and tools needed for each specific step. This focused approach not only simplifies the task for Operators but also enhances efficiency and clarity in the production process, reducing opportunities of human error.

Standard Work Instruction Examples: Assembly

Work Instruction Examples 2: Incoming Inspection

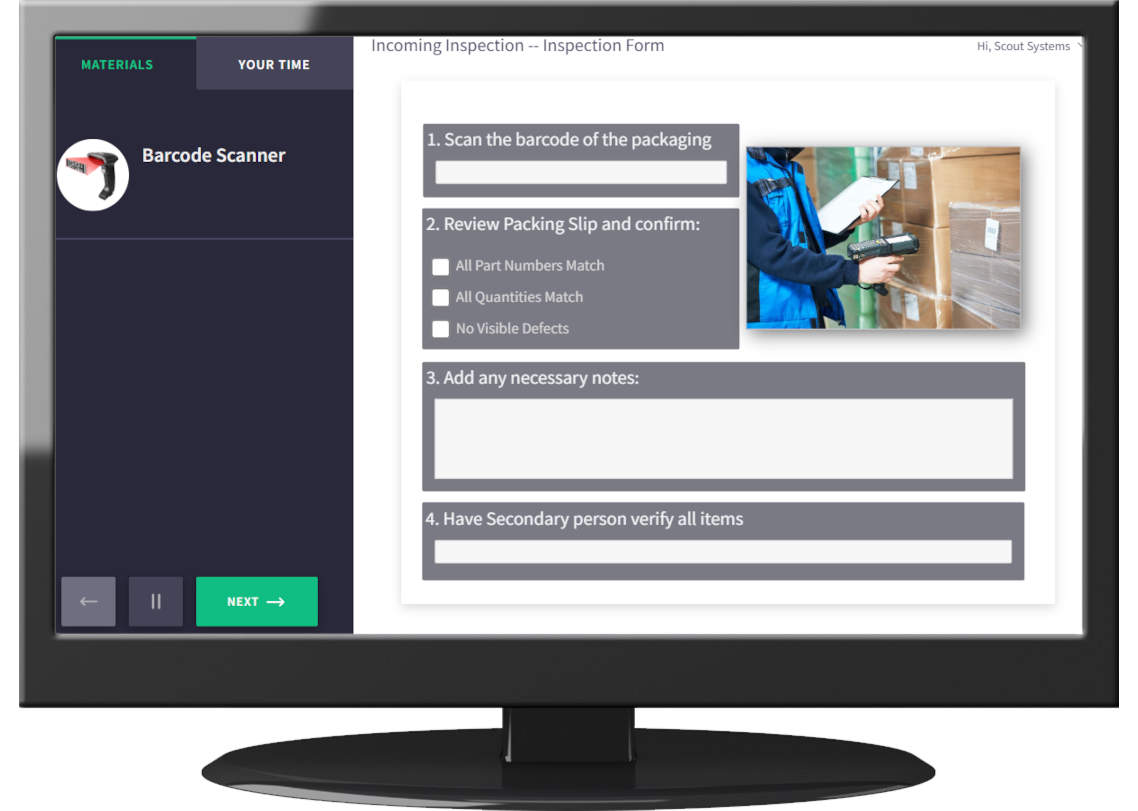

A key advantage of using Work Instruction Software lies in its capability to incorporate input fields, serving not only as a guide for Operators but also as an integral tool for in-line quality assurance. These input fields are particularly useful for procedures like incoming inspections, enabling serial tracing of products, checklist verification of completed steps, collection of notes, checking of measurement fields, and facilitating inspector sign-offs, among others. The Picture-in-Picture feature further enhances training by streamlining the interface, offering Operators a clear and focused view of their tasks, thereby simplifying the process and ensuring accuracy in execution.

Standard Work Instructions Examples: Incoming Inspection

Work Instruction Examples 3: CNC Machines

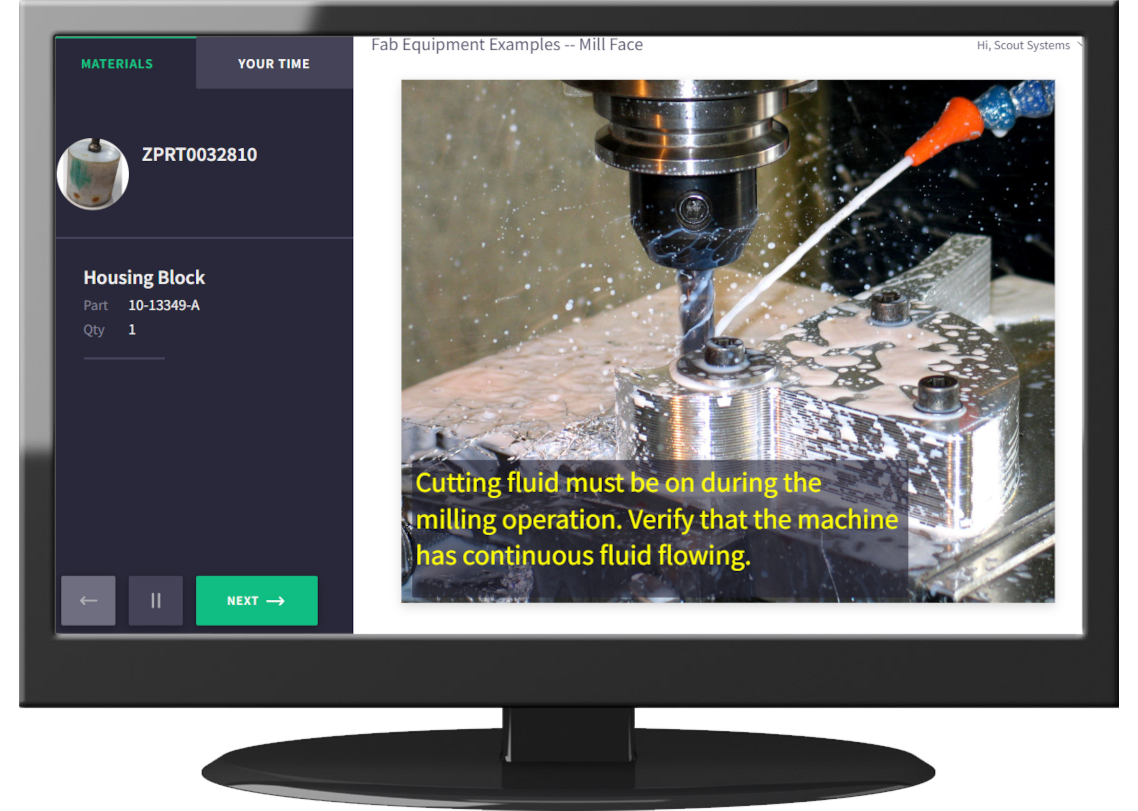

For automated machinery like CNC Mills, work instructions shift the purpose towards optimizing setup times and enhancing data collection. Integrated with Tracker, our work instruction platform captures equipment signals to accurately log both the cycle time and the value-creation duration of a production process. It's essential that the images incorporated within these instructions vividly depict the crucial processes that Operators need to monitor closely, ensuring precision and efficiency in every step of the operation.

Standard Work Instructions Examples: CNC Machine

Work Instruction Examples 4: Press Brakes

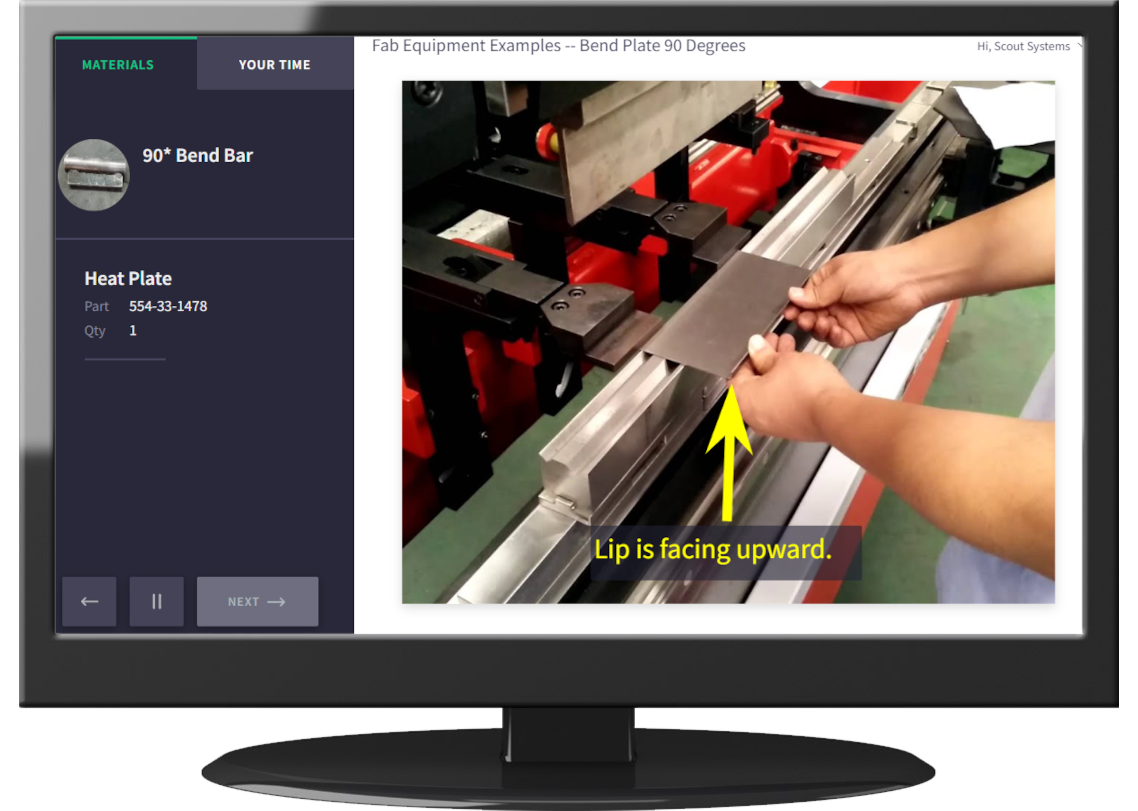

Work instructions play a pivotal role in preventing common errors at the Press Brake, such as backward bends. When these instructions are enhanced through integration with Tracker, the system not only captures machine data but also leverages signals to automatically advance the instructions for the Operator. This automation ensures that after each bend, the work instruction software progresses to the subsequent step without manual input. This methodical, step-by-step guidance provides Operators with visual references for product orientation, significantly reducing the likelihood of mistakes and streamlining the bending process.

Standard Work Instructions Examples: Press Brakes

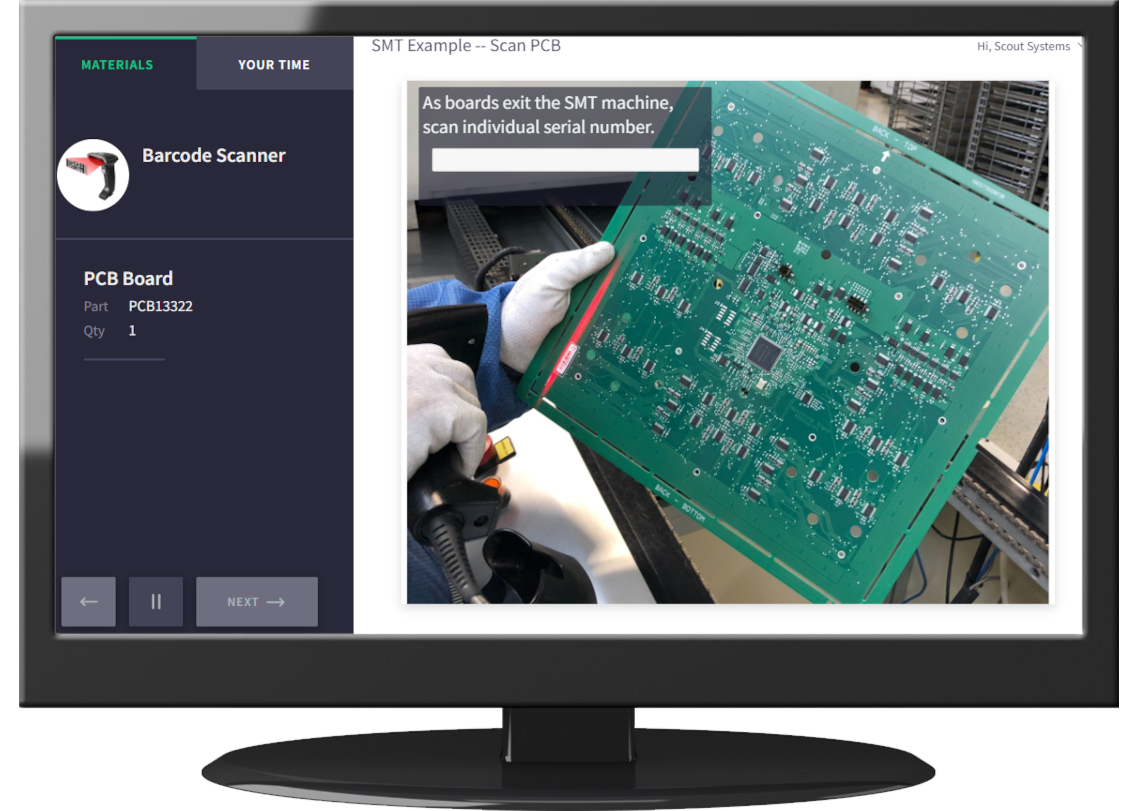

Work Instruction Examples 5: SMT Line

Due to the precision of surface-mount technology (SMT), the focus of work instructions shifts from detailed process guidance to overseeing the operation's entirety and ensuring the quality traceability of the final product. The integration of Tracker into this environment empowers manufacturers with precise cycle times for each item produced, enabling a clear view of productivity and efficiency. Should a bottleneck occur, causing machine slowdowns, Live Production displays real-time alerts, promptly informing Production Supervisors of any arising issues. For Operators, the instructions typically emphasize the inspection steps or, in cases where unique serial numbers are involved, facilitate serial traceability through specific input fields. This approach ensures that every aspect of the SMT process is monitored, traced, and optimized for quality assurance and operational excellence.

Standard Work Instructions Examples: SMT Line

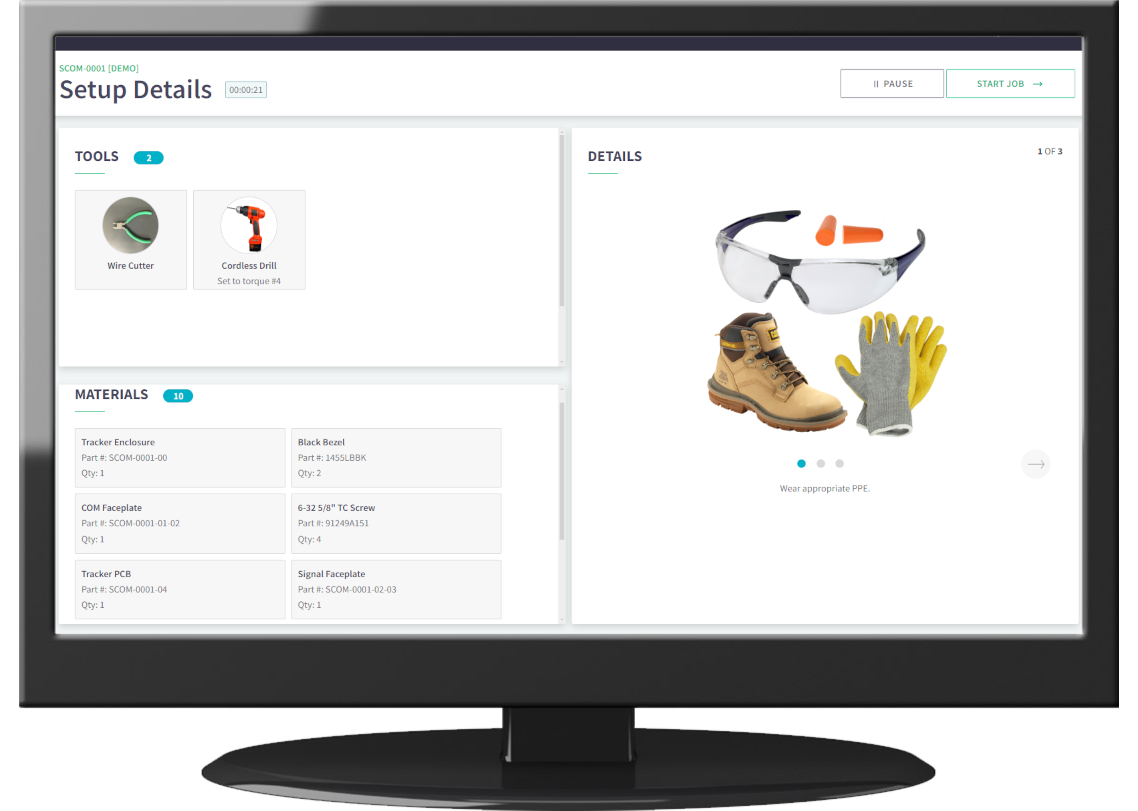

Bonus Example 1: Setup Work Instructions

Scout Systems’ work instruction software streamlines the creation of Setup Work Instructions, significantly easing the documentation process. By aggregating specific tools and materials mentioned in production instructions into a comprehensive top-level BOM/Tool list, it presents Operators with all necessary details at the onset of a production order. This feature not only simplifies the role of the documentation controller, requiring minimal additional input for production preparation but also ensures that setup instructions are thorough, covering essential PPE, material organization, and any required tool or machinery configurations. This holistic approach to setup instructions enhances efficiency and ensures a smooth transition into production phases.

Standard Work Instruction Examples: Setup

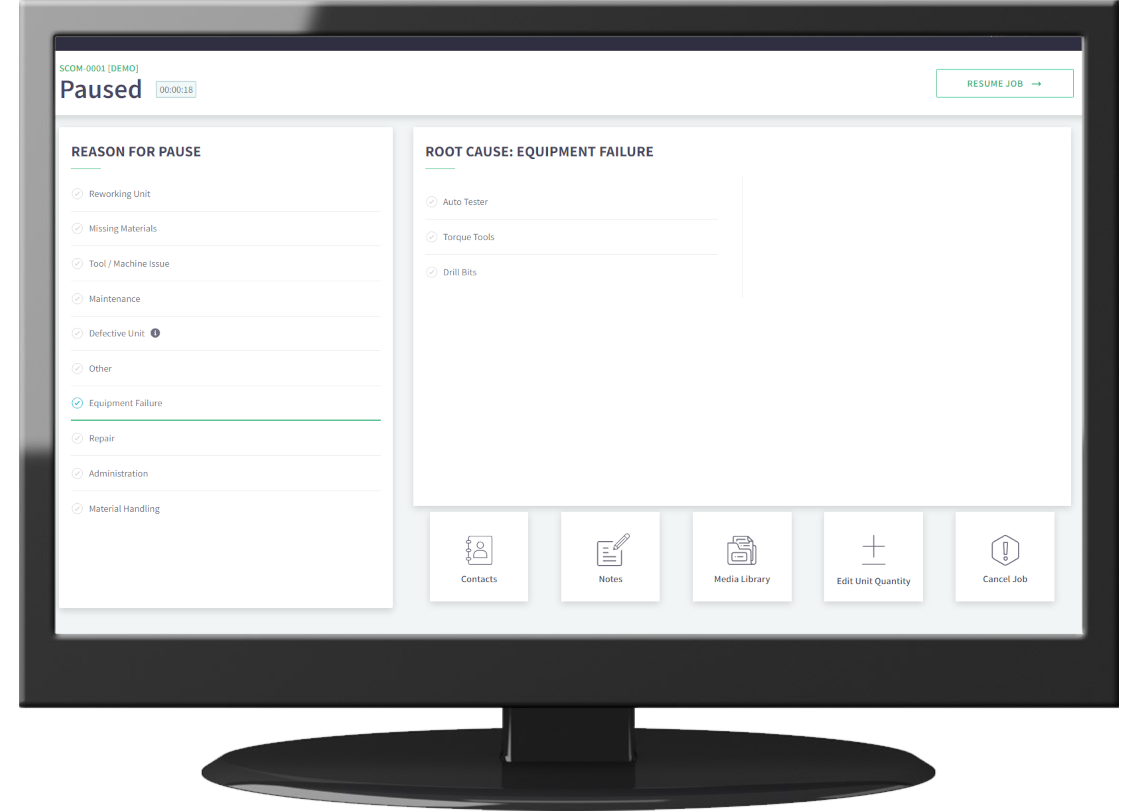

Bonus Example 2: Recording Waste

Understanding that production processes may encounter challenges despite providing Operators with detailed guidance, our platform includes a feature to monitor production waste effectively. In instances where value-added work ceases, Operators can utilize the Pause function to stop all timers and initiate waste tracking. Resuming Production mode mandates the selection of a cause for the pause, ensuring accountability and insight into process interruptions. The reasons for pauses, along with their root issues, are fully customizable for each Work Area. This flexibility allows for precise monitoring and analysis of factors impacting efficiency, enabling targeted improvements and strategic interventions to enhance overall productivity.

Standard Work Instruction Examples: Production Waste Collection

Explore Today for Free

Embarking on the digital transformation journey with legacy systems for work instruction creation may seem adequate initially, but as the vision for a fully digital factory comes into focus, the limitations become apparent. Starting with our free work instruction software not only sets the foundation for this transition but also offers a glimpse into the substantial benefits of adopting a platform designed specifically for manufacturing environments. Experience firsthand how the right software can significantly reduce labor costs and enhance production processes, paving the way for a more efficient and innovative future in manufacturing.

Richard Mason

By day I help people solve problems, by night I'm enjoying IPAs! For fun I work in my garage building gadgets that cost way more than they are worth.

3 min read

3 min read